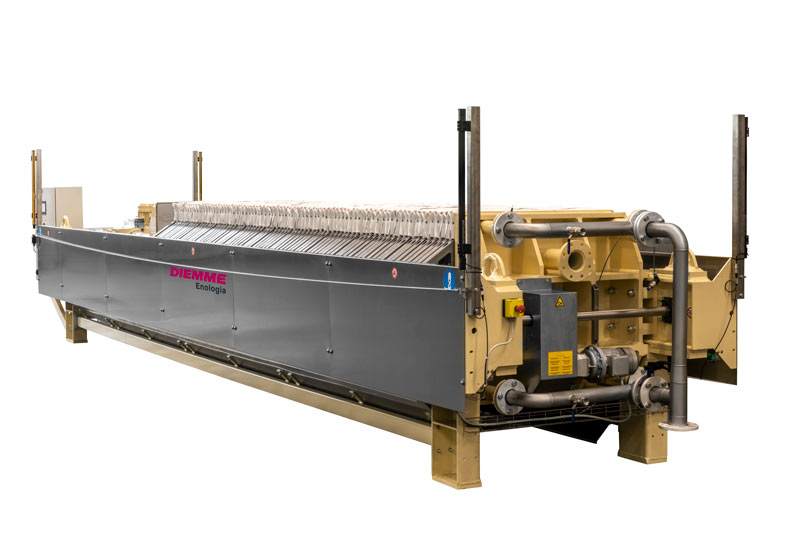

Plate filter

Filter press

Technical description

The chamber filter press APS is an industrial plant for the dehydration, by solid/liquid separation, of suspensions with a high solid content.

The filter press consists of a series of plates and filter cloths. Between these alternating layers chambers are created in which a solid, dehydrated cake is formed. In the cavity between the plate and the frame, the solid phase is retained and only the liquid phase, with a low solid content, can escape. Filtration is the main phase of the filtration process.

The pumped product may or may not contain filter aid. Filtration causes clogging of the filter cloths, an increase in the pumping pressure and thus a reduction in the flow rate. In the first phase of the filtration cycle, a progressive cavity pump is used. During this phase, the pressure is low and the throughput is high. When the pressure exceeds 5 or 6 bar, the eccentric screw pump is switched off and a piston pump with a smaller flow rate generates the increased pressures (up to 12 bar). The filtration cycle is finished when the filtration pressure exceeds 12 bar continuously for a certain time.

The filter press processes:

- Grape must

- Wine

- Must lees from sedimentation and flotation

- Fining trub and lees

Automation

The APS 1000 and 1200 filter press models can be equipped with automatic, pneumatically controlled or manual throttle valves. The models with automatic valves can perform filling, filtration and emptying automatically, with minimal operator intervention. The models with manual valves require only one operator intervention each for filling, filtration and emptying.